Limestone is one of the most common materials used in construction and industrial applications. Its widespread availability and versatility make it a critical resource for various sectors. However, not all limestone is created equal, and its material properties play a significant role in determining the most appropriate limestone crusher machine. Understanding the nature of limestone and how different characteristics affect crusher selection is essential for optimizing the efficiency and performance of crushing operations. This article explores how factors like hardness, moisture content, and abrasiveness influence the choice of limestone crusher machines.

Before selecting the appropriate crusher, it is crucial to understand the material properties of limestone. These include hardness, moisture content, and abrasiveness, which can all have a substantial impact on crushing efficiency. Each of these factors affects how the crusher functions and the wear it will endure during operation. Therefore, analyzing the specific characteristics of the limestone in question is fundamental to achieving an optimal result in the crushing process.

Hardness is one of the most influential material properties when selecting a limestone crusher. The hardness of limestone is typically measured using the Mohs scale, which ranks materials based on their ability to resist scratching. Limestone, depending on its composition and impurities, can range from soft to moderately hard. This hardness determines the type of crusher that will best handle the material.

For softer limestone, a jaw crusher may suffice, as it efficiently breaks down the material through compression. However, for harder limestone varieties, a more robust crusher, such as a cone crusher, may be required. The cone crusher can provide the necessary force to fracture harder materials without excessive wear. Selecting the correct aggregate crusher based on the hardness of the limestone is crucial to avoid unnecessary damage to equipment and to maintain optimal processing speeds.

Moisture content in limestone can significantly affect the crushing process. High moisture levels can cause the limestone to become sticky, leading to clumping and clogging in the crushing system. This can result in reduced throughput and increased maintenance. Crushers designed to handle wet materials, such as hammer crushers, are more suitable for dealing with moist limestone as they prevent material buildup and offer better discharge flow.

On the other hand, dry limestone, which has lower moisture content, can be processed more efficiently in traditional impact or jaw crushers. These crushers do not face the same challenges related to clogging, and their ability to break down dry limestone into smaller particles ensures a faster and more efficient operation. Understanding the moisture content of limestone before choosing a crusher type can help avoid processing inefficiencies and reduce operational downtime.

The abrasiveness of limestone is another critical factor that influences the choice of crusher. Limestone with a high abrasive content can cause significant wear on crushers, leading to more frequent maintenance and increased operational costs. Abrasive limestone wears down crusher parts like hammers, jaws, and liners more rapidly, requiring materials that are more resistant to abrasion.

For highly abrasive limestone, machines like impact crushers or vertical shaft impact crushers (VSIs) are often preferred. These crushers are designed with materials that can withstand the increased wear caused by abrasive particles. Using crushers with adequate wear protection and more durable components is essential for minimizing maintenance costs and ensuring the longevity of the equipment.

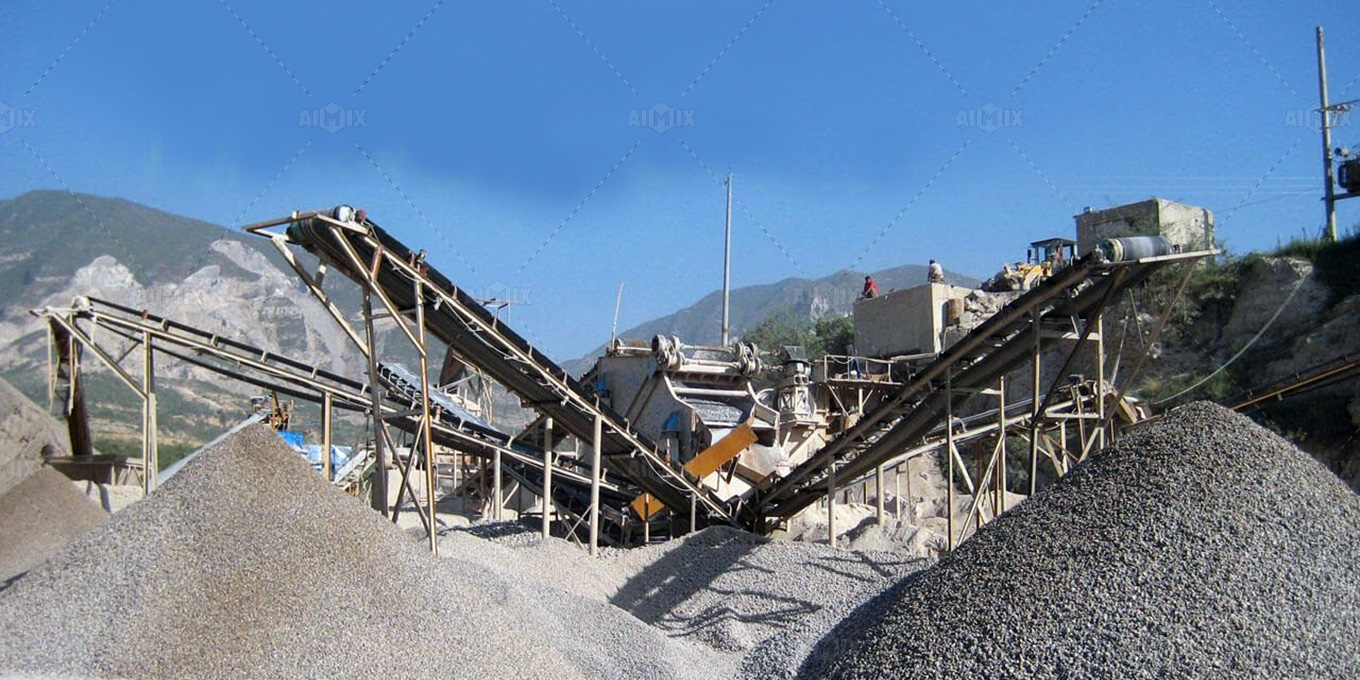

The material properties of limestone – hardness, moisture content, and abrasiveness – must be carefully matched with the appropriate crusher type to ensure maximum efficiency and profitability. Different crushers are engineered to handle specific challenges posed by these properties, and understanding the relationship between material characteristics and crusher design is key to achieving optimal results.

Jaw crushers are commonly used for crushing softer limestone. These machines apply compression to the material between two surfaces to break it into smaller pieces. Since mobile jaw crusher for sale is simple and robust, they are ideal for handling less abrasive limestone with moderate hardness. However, they may not be the best choice for harder or more abrasive limestone types, as they could experience more rapid wear.

Cone crushers are designed to handle more challenging materials. Their unique mechanism, which involves compressing the material between a stationary cone and a rotating cone, makes them more suitable for harder and more abrasive limestone types. Cone crushers are highly efficient and provide a more consistent product size, making them ideal for high-volume operations.

Impact crushers and hammer crushers are more versatile machines that can process both moist and highly abrasive limestone. Impact crushers use high-speed rotors to throw material against impact plates, while hammer crushers rely on rotating hammers to crush the material. These crushers are particularly well-suited to wet or sticky limestone, as they can break the material more effectively without clogging the system.

The selection of a limestone crusher is not a one-size-fits-all decision. Each limestone deposit is unique, and its material properties must be thoroughly evaluated before selecting a crusher. Hardness, moisture content, and abrasiveness are the primary factors that should guide this decision. By understanding how these properties affect crushing efficiency and wear, businesses can select the most appropriate crusher for their specific needs, resulting in enhanced operational efficiency, reduced downtime, and lower maintenance costs.