For a business whose livelihood is hewn from rock and mineral, the decision to invest in a crushing plant is profoundly consequential. It represents not merely a capital expenditure but a foundational commitment to operational capacity, efficiency, and future growth. Approaching this decision through the narrow lens of initial purchase stone crusher plant price is a common and often costly misstep. A truly strategic investment requires a more holistic and discerning analysis, one that contemplates the entire lifecycle of the asset and its alignment with long-term ambitions. This journey demands careful consideration of technical specifications, supplier reliability, and the often-overlooked soft costs that ultimately determine the true value of the investment.

An exclusive fixation on the bottom-line number on a quotation can be dangerously seductive. It offers a seemingly simple metric for comparison. However, this myopia obscures the more significant financial realities that will unfold over years of operation. A lower initial cost may camouflage compromises in material quality, engineering sophistication, or component durability. These compromises inevitably manifest as elevated downtime, exorbitant maintenance expenses, and a truncated operational lifespan. The genuine measure of value is not the purchase price but the cost per ton of material processed over the plant's entire service life. This metric encapsulates efficiency, reliability, and longevity, painting a far more accurate picture of the investment's wisdom.

Before soliciting a single quotation, introspection is paramount. A clear understanding of your specific needs forms the bedrock of a sound decision. This goes beyond basic capacity requirements. Consider the geological characteristics of the material to be processed; its abrasiveness, hardness, and silica content will dictate the necessary robustness of the machinery. Analyze your production goals not just for today, but for the foreseeable future. Is scalability a requirement? Furthermore, contemplate site-specific constraints, such as spatial limitations, environmental regulations, and mobility needs. A plant that is perfectly adequate for a large, stationary quarry operation would be ill-suited for a contractor moving between smaller job sites. Articulating these operational and strategic imperatives creates a definitive checklist against which all options must be measured.

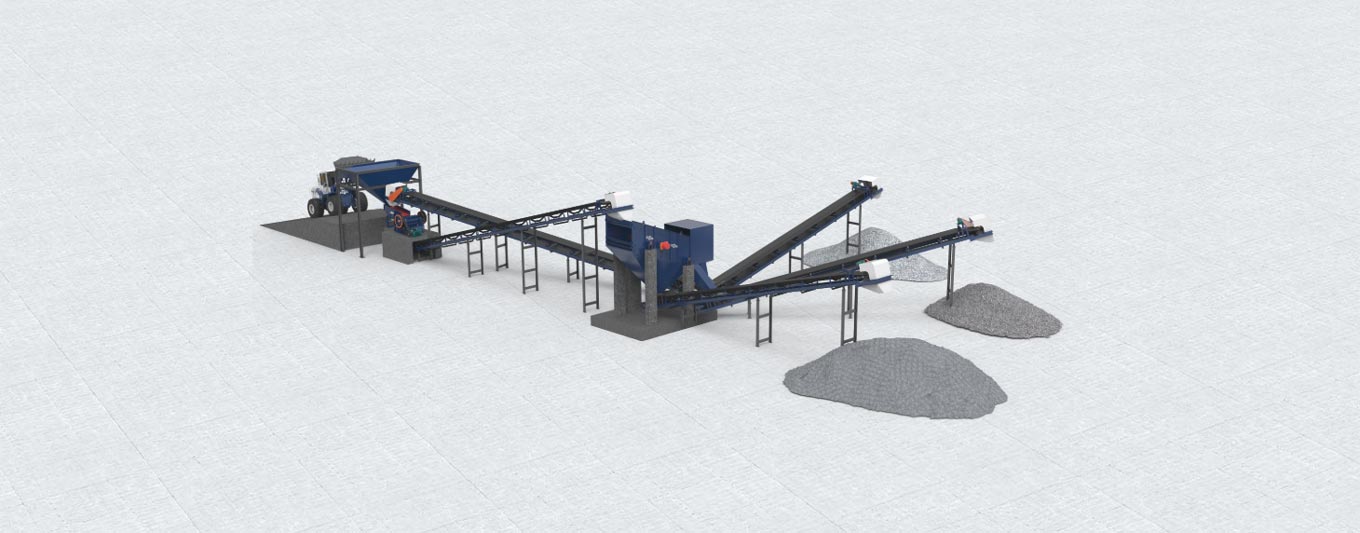

A crushing plant is a complex symphony of interconnected components, each contributing to the overall cost and performance. The primary crusher—be it a jaw, gyratory, or impactor—forms the heart of the operation, and its selection is critical. Secondary and tertiary crushers, along with screens, conveyors, and hoppers, complete the circuit. The pricing is influenced by the size and capacity of these units, the grade of steel used in their construction, and the quality of bearings and other wear parts. Technological nuances, such as automated control systems for optimizing settings and monitoring performance, represent an additional layer of cost but also a significant source of long-term efficiency and consistency. Modern plants often incorporate sophisticated automation that minimizes human error and maximizes output.

Perhaps the most underestimated aspect of crushing plant pricing is the intangible value embedded in the crusher machine manufacturer's expertise. The engineering prowess behind the design of the plant layout is not a line item on an invoice, but it is invaluable. A well-conceived flow diagram minimizes bottlenecks and ensures seamless material transfer, directly impacting productivity. The availability and depth of technical support, the comprehensiveness of training provided to your personnel, and the robustness of the warranty offered are all critical factors. A supplier that provides exceptional post-sale support is investing in your success, effectively reducing your operational risk. This support network is a vital asset that contributes immensely to the plant's overall value proposition.

The procurement process should be treated as a rigorous due diligence exercise. Scrutinize potential suppliers beyond their marketing materials. Investigate their reputation in the industry, their financial stability, and their track record for honoring warranties. Request references from existing clients with similar applications and contact them to discuss their experiences with reliability and support. Crucially, move beyond simple price comparisons and insist on a detailed lifecycle cost analysis. This document should project not only the initial investment but also estimated costs for energy consumption, routine maintenance, wear parts replacement, and potential downtime over a defined period, such as five or ten years. This analysis will reveal the true economic frontrunner.

The final negotiation should be approached with the mindset of forging a long-term partnership. The objective is not to secure the lowest possible price at the expense of the supplier's viability, but to arrive at a fair agreement that ensures a mutually beneficial relationship for years to come. Discuss service level agreements, spare parts availability, and potential future upgrades. A collaborative relationship with your supplier can yield dividends in the form of prioritized support and valuable operational insights. The mobile crushing plant will be a core component of your business infrastructure for a long time. Selecting the right partner to accompany you on that journey is a strategic decision of equal importance to the machinery itself. This thoughtful, comprehensive approach transforms a significant capital outlay into a deliberate investment in your enterprise's resilience and future prosperity.